3D PRINTING SERVICES

What we can do for you:

Using our range of 3D Printers, we are able to offer a bespoke service covering various types of 3D models. The six categories below are an indication of the broad uses of 3D printed models to help provide an idea of what we are able to print. We work with a small team and a limited number of 3D printers, therefore there may, at times, be a slight wait for the prints to be completed.

Our service is open to staff, students, local companies, individuals and organisations to assist in their development of prototypes and new product development, bringing their ideas to life. We are also approached by individuals wanting to replace broken parts, build mock scenes (heritage, railway, doll houses and similar), or create custom accessories, and open to many other models that may be requested.

On receipt of your CAD or 3D file, we will review the complexity of the model and analyse its readiness to print through our printer software. A quote will be provided based on the material required, whether further work is required to print the file and the time it will take to print. Should you not have a CAD or 3D file, but have an idea and sketches , we can create the 3D model for you. We will provide a quote for how long it would take to create your design, ensuring the 3D model matches your concept and sketches provided. Your model can then be printed for which a separate quote will be provided.

If you are agreeable to the cost(s), we will then go ahead and print your 3D file, and notify you as soon as it is completed. We can send the model to you or you can collect from the University.

Game, Character & Toy Assets

Architectural & Heritage Models

Engineering & Product Prototypes

Most game and toy assets, including 3D character design will be modelled in a freeform modelling sfotware such as Maya, Cinema 4d, Blender, 3DS Max or ZBrush. The majority of these programmes will export to the STL format for 3D printing.

Most architectural models would be built with CAD software such as Autodesk Revit, Graphisoft ArchiCAD or Sketchup which provide the ability to export as an STL file. For models built within non CAD based software such as Blender, there should still be an export to STL function available.

Most engineering or product design models will be built with CAD based software such as Autodesk Fusion 360, Autodesk Inventor, Solidworks or smilar. Each should have an export to STL function.

Accessories & Jewellery Design

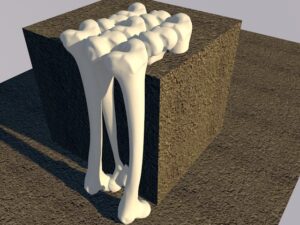

Skeleton & Medical Parts

Repair Parts

Most jewellery design models will be built with CAD based software such as Autodesk Fusion 360, Solidworks, Sketchup or smilar. Each should have an export to STL function. Similarly, freeform modelling software which may be used should also be able to export to STL for 3D printing.

Most skeletal and human body parts are generally modelled in CAD or freeform modelling software such as 3DS Max, Maya, Blender or Cinema 4D. Each programme exports to a 3D printing format such as STL. Medical equipment is more likely to be modelled using CAD software such as AutoCADand Fusion 360.

Depending on the type of repair part, the range of software that could be used is similar to each of the other more CAD based programmes – these Anglo Saxon pots were modelled in 3DS Max at miniature scale for an Anglo Saxon scene, based on broken pottery.

How to Order your 3D Print

Step 1:

You may either complete the Quotation form below to receive a quote for the cost of your 3D print and expected time scale or speak first with one of our team, Sam Barker, who leads the 3D Printing Service within CEDI. His contact details are here.

Sam would be able to provide advice with regards the material you may require. He would, though, need to see your model to be able to provide advice regarding the time and cost, therefore you may want to email your model at the same time as contacting Sam.

Step 2:

Having received your requirements either by completing the Quotation form or from discussing your requirements with Sam, a specification brief will be created with a quote for the time and cost.

Step 2-1

If your project requires a 3D model to be generated from sketches, we will first carry out a consultation with you to ensure we can create the 3D model to match your required specifications.

Step 2-2

After the consultation we will provide a quote for creating your 3D model. This will include either a further visit to ensure the 3D model created matches your requirements, or images including a 360 animation, emailed to you for approval and ‘sign-off’. Should the model need amendments, we will amend and re-send. The quote will include two proofing passes to ensure the model matches your requirements.

Step 2-3

Once the model has been signed off, the quote for the development of the 3D model will be added to the Specification Brief and Quote document as in Step 3 below, and the 3D model will be prepared printing.

Step 3:

The next step if you are happy for the 3D print to go ahead, then please confirm using the acceptance slip at the bottom of your Specification Brief & Quote document. You will also need to pay for the print at this point. You can pay via PayPal on this link or using the instructions provided on the Quote document. Once the Acceptance Slip and payment has been received, your model will be set to print.

Step 4:

You will be notified as soon as your print is completed. You may either collect in person at the University, or we can send it to you at standard postage rates, dependent on size of package and weight.

Quotation Form:

Upload your Model Form:

File Formats:

The most commonly used file formats for 3D printing are 3MF, STL, OBJ, X3D, PLY, Collada (DAE) and WLR (VRML97/2). A few of the formats can include colours or textures in the file, for example 3MF, PLY, VRML, X3D, and Collada. Other formats store the texture in a separate image file such as GIF, JPG or PNG and map-file (OBJ). If in doubt, please ask and we will be able to advise and take you through the export process from your 3D modelling software.

3D PRINTING MATERIAL TYPES AVAILABLE

PLA

ABS/ASA

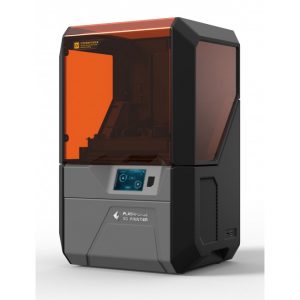

SLA/RESIN

PLA: Polylactic Acid is one of the most popular materials used for 3D printing. It can be printed at a low temperature and generally does not need a heated bed. It is a thermoplastic made from renewable resources such as corn starch, tapioca roots or sugar cane, and therefore seen as a more ecological 3D printing material. It can be sanded to provide a smoother model, plus the supports can be easier to remove than other material types.

ABS: Acrylonitrile Butadiene Styrene is one the first plastics used for 3D printing. It is a low cost plastic, has a smoother finish than PLA and is known for its durability (LEGO bricks are made with this material). ABS needs a heated bed, and is able to be printed at high tempertures, it should, therefore, have a suitable enclosure.

SLA/RESIN: Stereolithography Apparatus, commonly referred to as Resin and is a another type of 3D printing which uses a high-powered laser to harden liquid resin contained in a reservoir. The printed 3D model requires rinsing in isopropyl alcohol (IPA) to remove any uncured resin from its surface. After rinsing, the model may require post-curing, a process which helps parts to reach their highest possible strength and stability.

Printers: Raise3D N2 Plus Dual Extruder 3D Printer or LulzBot TAZ 6

Temp: LOW

Cost level: LOW

Strength: LOW

Colours Available: White, Black, Red, Yellow, Blue, Orange, Grey & Art White

Printer: Raise3D N2 Plus Dual Extruder 3D Printer or LulzBot TAZ 6

Temp: HIGH

Cost level: LOW

Strength: GOOD

Colours Available: White, Black & Grey

Printer: FlashForge Hunter

Temp: USES LIGHT

Cost level: HIGH

Strength: VERY GOOD

Colours Available: Clear, Draft, Grey & Colour Kit

We have formed links with local 3D printing companies, therefore, depending on demand and volume of 3D printing, we may be working with these companies to ensure your models are supplied on time. Large 3D prints may also need to be printed by these external companies as our current largest print size, with the Raise 3D printer, is (W+D+H):

Single Extrusion Print: 12×12×23.8 in / 305×305×605 mm

Dual Extrusion Print: 11×12×23.8 in / 280×305×605 mm

The Luzbot Tas Printer maximum build size is (W+D+H): 11.02×11.02×9.80 in / 280×280×250mm

The Flash Forge Hunter Resin Printer maximum build size is (W+D+H): 120×67.5×150mm

3D Modelling Services

Via our CEDI team, 3D students and graduates we are able to provide a service to model items on request. This can be any item which can be used for 3D printing purposes, game assets, prototypes, heritage and museums, for VR, AR or mixed reality. We can discuss your ideas and work them up into 3D models and scenes which can be for your use alone or added to our library of 3D models and assets for general use. Please contact Dr Debs Wilson for more information or to discuss your 3D modelling requirements.

We have a range of 3D modelling software we can use to suit the purpose of your 3D model concept. The team are able to use CAD based and freeform modelling such as 3DS Max, Maya, Cinema 4D and Blender, taking models into other environments such as Unity and Unreal. The most important aspect will be to ensure we have reference visuals, descriptions/technical details and dimensions (if known) to build a realistic interpretation of your concept and requirements. Please see the above process (Steps 2-1 to 4) with regards to how we will work with you, and how we will determine the cost involved as a 3D model and as a 3D printed model.

Many of the 3D models can be uploaded to CEDI’s Enterprise page on Sketchfab, with heritage content available via our Heritage page . Our Enterprise Sketchfab account also enables the sale of the 3D models, promoting the models to an international audience. Models can also be viewed via Sketchfab, either in VR, 360s or still images. The models can also be downloaded from the Sketchfab site for personal use.

Computer Aided Design

Freeform 3D Modelling

3D Model Analysis

There are many CAD software packages you can use for creating a 3D model. At CEDI, we use Autodesk’s AutoCAD and Fusion 360 for product design, and Autodesk Revit and Graphisoft ArchiCAD for architectural and heritage building models. We are able to help you in choosing the best software for your project or create the model for you.

There are also many 3D freeform modelling software programmes for creating characters, and non technical based 3D models. At CEDI we use Autodesk 3DS Max and Maya, Maxon Cinema 4D, Blender, ZBrush and Rhinocerous 3D. We can also create scenes using Epic’s Unreal Engine and Unity Game Engine.

Using the latest in 3D Software we can fix and analyse where necessary to make sure you receive the optimum 3D Print from your file. The 3D printers come with their own analysis and slicing software to ensure the 3D model is ready to print. Problems that can occur are overlapping polygons/faces, insufficient wall thicknesses, or inverted polygons ie polygons facing the wrong way.

We are also able to create 3D models via Photogrammetry and our 3D Scanner (see our Resources page). 3D scans provide realistic image based 3D models which are very useful for items that exist. This technology can be used to acquire reliable measurements and produce 2.5-D geometric models through overlapping either aerial or ground-based photographs (also referred as 2-D imagery).

Many visual 3D models, such as those intended for games, only have surface visual purposes, they do not have a thickness or in the case of buildings, a wall thickness. 3D printers require information about how thick the wall of the model is or if a solid model print is required.

3D Printing Resources

Raise3D N2 Plus Dual Extruder 3D Printer

Competitive and scalable; the Raise3D Pro2 Plus improves upon its award-winning predecessor and provides the next generation of performance.

A cube-shaped printer packed up with industrial grade components

being ready for short-run manufacturing. Coping with the most geometries,

this printer runs incessantly while handling the strongest materials. A toiler, set

to integrate a print factory.

Supported Materials: PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glass Fiber Infused / Carbon Fiber Infused / Metal Fill / Wood Fill

FlashForge Hunter

The FlashForge Hunter is a DLP (Digital Light Processing) 3D Printer, which allows a user to a print a 3D model in highly-detail. Photopolymer resin is adopted as a printing material for Hunter DLP 3D printer. It can 3D print a whole layer of 3D model at one time, the printing time is generally consumed less than that of the SLA 3D printer. Especially useful for making tough highly detailed engineering prototype, castable ring model, or even making medical models.

The build plate can be replaced quickly and there is no need for calibration. That means faster printing speed and easier to do post treatment.

Supported Materials: 3MF / STL / OBJ / FPP / BMP / PNG / JPG / JPEG / GX/G

Resin Curing Equipment (FormLabs)

The Form Cure is a UV post-curing station that’s been specifically designed to accomodate parts printed by the Form 2 3D Printer. The chamber is heat adjustable up to a temperature of 80 °C, and models are bathed in a 405 nm UV light source courtesy of 13 multi-directional UV LEDs.

Compatible with all Formlabs Resins, including all Standard Resins (Clear, White, Grey, Black), Engineering Resins (Tough, Durable, Flexible, High-Temp) and Jewellery and Dentistry Resins, the Form Cure triggers the chemical reaction required for the resins to reach their desired mechanical properties.

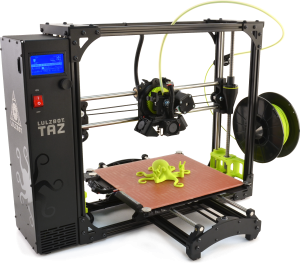

LulzBot TAZ 6

Engineers, designers, educators, and makers agree: The LulzBot TAZ 6 is the most reliable, easiest-to-use desktop 3D printer ever, featuring innovative self-leveling and self-cleaning, and a modular tool head design for flexible and multi-material upgrades. With proven 3D printing technology and one of the largest print volumes in its class, the LulzBot TAZ 6 is ready to work.

3D printing is more reliable than ever with the integrated automatic bed leveling system, all metal LulzBot v2 Hot End, and heated PEI print surface. With the all metal hot end, you can take advantage of the cutting edge market for new materials. Perfect for both large and small objects, the heated PEI build surface keeps your 3D printed objects in place when hot and releases when cool. With Cura LulzBot Edition, you have hundreds of quickprint profiles built in for seamless 3D printing.

Supported Materials: PLA / ABS / HIPS / PC / TPU / TPE / NYLON / PETG / ASA / PP / PVA / Glass Fiber Infused / Carbon Fiber Infused / Metal Fill / Wood Fill